How to make (and use!) stencils

Table of Contents

- What is a stencil?

- How to make a stencil

- How to use a stencil

What is a stencil?

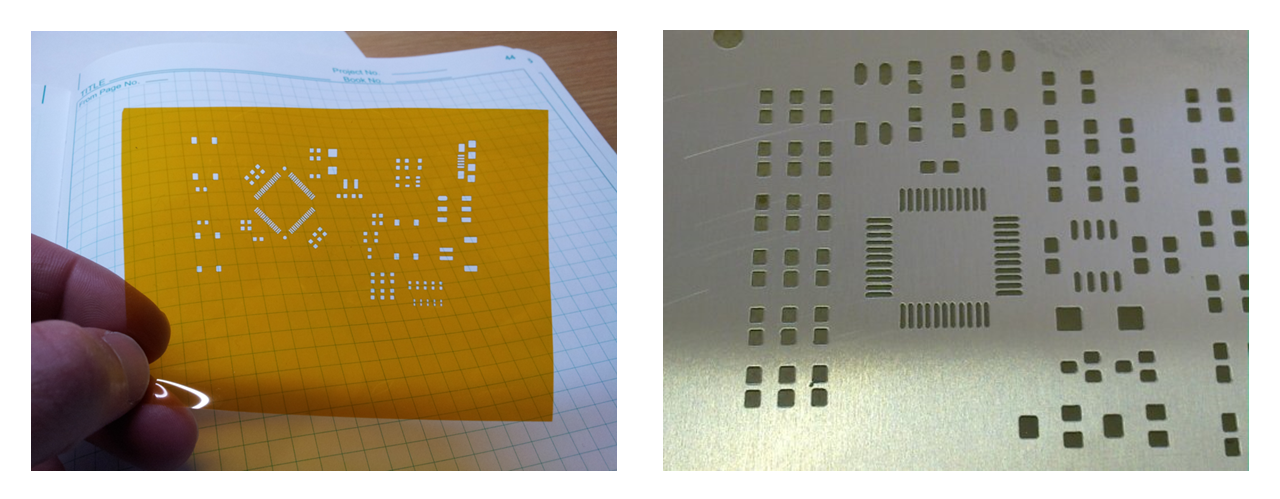

A stencil is a material with cutouts that enables solderpaste to be more easily and precisely applied prior to component placement and reflow. (If you don't know what I mean by 'reflow', or want more information about that process, see our “Reflow Oven” page for more.) Stencils can be made with a variety of materials; the images below show two very common ones (polyimide on the left, and stainless steel on the right) (Source for images). Kapton tape (also polyimide) is another low-cost option. The Hive has 5mil polyimide sheets for stencil fabrication that are free for users, as well as Kapton tape. We also have (courtesy of Stephan Strassle) recipes for using PET projector transparency sheets between 0.5 and 10 mil thick.

Stencils are by no means a required or necessary step for completing your PCB. They are very useful if you have many surface-mounted components (SMDs), SMDs with many pins or fine-pitch pins, or have a few SMDs but many identical boards. They do not work for through-hole components! Those must be done by hand.

How to make a stencil

Stencils can be fabricated at The Hive using the LPKF ProtoLaser U4. The process detailed here is for 5 mil/0.125mm polyimide ONLY. The Hive provides this material free of charge to our users. For other accepted materials, you'll have to adapt the process below. Stainless steel is not allowed in the ProtoLaser!! If you require a stainless steel stencil, please email us (hive-pcb@ece.gatech.edu).

NOTE: If you're using the PET sheets (Amazon link), the material settings should be labeled “PET_<thickness>um” (there might be an “ss” in there somewhere as well, for the creator) for whatever thickness in um (microns, NOT mils) you're using. The process below will be the same other that the material settings selection.

(If you have never used the ProtoLaser before, you'll need to be trained prior to use; see this page for details on that. Stencils made of non-metallic materials, like polyimide, can also be made with our laser cutters, but that's beyond the scope of this write-up.)

Note: This process is detailed in the LPKF ProtoLaser's “How-to” document, which can be found both here, and on the ProtoLaser itself (in the “ProtoLaser Docs” folder on the Desktop). See section 4.1, p. 120.

Before you start, you'll want to make sure that you have your solderpaste gerber files ready, along with your piece of polyimide. Note that we (typically) have either full 8×12 sheets, or a 24“-wide roll. If you need a full sheet, use one. Otherwise, use scissors to cut an appropriately-sized piece from the roll, making sure to leave enough room for a sizeable (~1 inch) frame/boarder around the design. Cut a large enough sheet for ALL stencils you'll be making (one per side of the PCB, if you have components on both sides - check your solderpaste gerber files).

- Log into the ProtoLaser. Turn on the tool and/or start the software if they are not already on and running. Brush off the processing surface; it needs to be clear of debris so that the polyimide can sit flat. Place your polyimide sheet onto the processing table and tape it down.

- It's advisable to tape it down as snug as possible. Unlike FR4, this will flap around during processing if it's not secured to the table. Taping all four edges works well.

- Start a new project (“File” > “New”).

- The template is called “THE-HIVE_Stencil” or something similar. It should be in the templates list at the top under “Custom Templates”, but if it is not, click “Browse” (lower left) and navigate to “Documents”. The stencil file should be there.

- “File” > “Import”, and select a solderpaste gerber file.

- Note that you need one stencil per side of the board, so only select a single gerber file. Put the Gerber onto the SolderPasteTop layer even if the gerber should be for the bottom solder paste, before clicking “OK”.

- Stencils don't have a side because they get cut through, so by adding all the Gerbers to the same layer (i.e. SolderPasteTop), it will etch them all at once.

- If you see a warning about nothing on a copper layer, just click “Continue”.

- If you have multiple solderpaste gerbers to import (i.e. multiple stencils to make, e.g. a PCB with components on both sides, or multiple PCBs), move your design out of the way (select all, right click, “Move Object”), and then repeat the previous step (the import step).

- After importing all your designs, move them around (left-click-and-drag to select them individually, right click, “Move Object”) to position them as you'd like them to be cut.

- “Toolpaths” > “Computer All” to compute the toolpath.

- If it has anything other than “Contour”, you've likely selected the wrong template, so go back to the start of this tutorial. Otherwise, shoot us an email.

- Click “Close” when completed.

- Move to the “Processing” tab to position your design on the polyimide sheet.

- Turn on the pilot laser (black laser button in the toolbar).

- Double-click on the processing area to move the pilot laser. Position it where you'd like the top-right of the design to sit on the polyimide sheet. Note that you want at least 1” of space between the edge of the sheet at the processed design.

- Right click > “Placement”, and then left-click-and-drag to move the design. Align the design with where you've placed the pilot laser.

- Move the pilot laser (double-click) to the corners of your design to confirm that the >= 1“ boarder exists for all four edges. If not, you will have to either move the design again (with the “Placement” window open), or you may have to cut a larger sheet of polyimide if you mis-judged.

- Once the design is properly placed within the polyimide, press the green play button in the toolbar (or “Processing” > “Process All” in the main toolbar) to begin processing. Follow the steps as requested.

- After processing, you may need to bend the stencil a bit to make sure all the little bits are out. Check with the jeweler's glass in the “PCB Tools” drawer to confirm if you can't visually confirm.

How to use a stencil

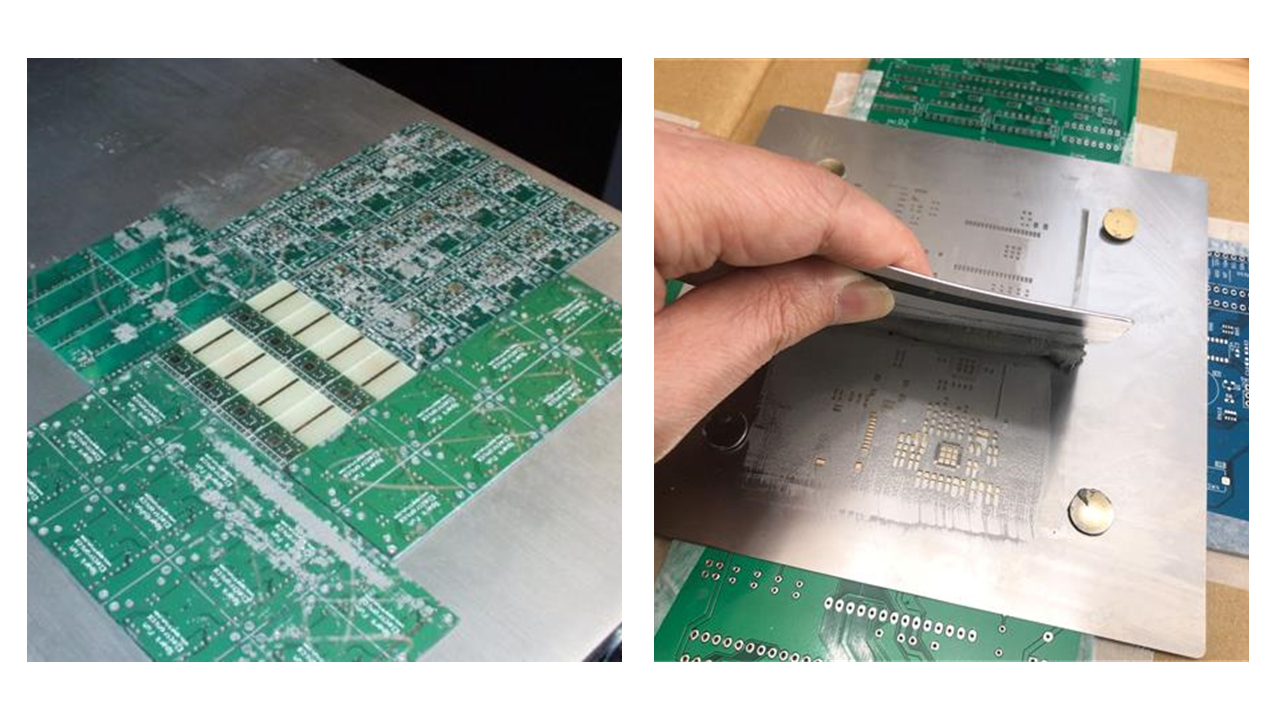

Once the stencil is fabricated, it must be aligned with the bare board underneath. The stencil should sit against the board as flat as possible! This is very important for applying the correct amount of paste, as well as not pushing paste underneath the stencil (rather than through the cutouts). Because the stencil is often cut out of a sheet of material larger than the PCB itself, often some unused PCB material of the same thickness (scraps or fresh, whatever you have) is used to surround the PCB and provide support to the stencil (see image below left (source)). Make sure to secure everything down so it doesn't move! Typically tape is used for this, but The Hive also has a fancy frame system that you can use (the LPKF ProtoPrint S).

Apply paste over the stencil using whatever tool you have, either a syringe, a wooden spatula/tongue depressor, whatever. You don't need a lot, so start with less than you think you need. (NOTE!! The reflow oven that The Hive has is optimized for lead-free solder paste, so if you're planning on using our oven, please make sure to use lead-free paste, or you'll be sad later.)

Then use a squeegee of some sort (credit card, ID, plastic scraper) to squeegee the applied paste across the stencil and into the cutouts (see image on right (source)). You shouldn't need to press down very hard, and again, maintain the stencil as flat against the board as possible.

You can always lift the stencil to check your progress, but you run the risk of ruining the alignment, so be careful.

Once the squeegee'ing is done, lift off the stencil and confirm paste is where you expect and not where you don't. If you got some excess outside where you wanted, that's okay, just scrape it off (because solderpaste is expensive, so we'll want to re-use as much as possible), then clean the PCB of any remainder, and try again.

NOTE!! The human eye is very good at detecting mismatched edges! However, this process is surprisingly tolerant, especially with regular-pitch components. Try not to be too picky. You can also always reflow again, or cut traces later if needed. It's a bit of trial and error to get a feel for this.

One other thing to note about this process is that it's extremely likely that it will look like the pads are shorted together, i.e. the paste will connect across pads. This is typically okay! When the paste melts, it will naturally wick to the nearby copper, which is hotter than the soldermask and/or the bare FR4. BE AWARE!! If you have a bare board, i.e. without soldermask, it's critical to etch copper away from between the pads, or you will get shorted pads later. This must be done prior to board fabrication. (Soldermasking can be attempted with Kapton tape, but YMMV and it's a very unsupported process. See this page for how you can try that.)

After the paste is applied to your satisfaction, move your board and all the components for placement to near where the reflow will happen (either a bench with a reflow station if you're a masochist, or near the reflow oven in the semi-clean room). You want to do the actual placement of components near to where the reflow will happen because the less you need to move the board with all your non-soldered-on components, the better. Using tweezers (we have plenty upstairs), place each component onto the PCB in the proper position. Double check the component and orientation prior to placement! You'll be sad later if you discover you put a key IC on backwards and fried it. Pin 1 is often indicated with a dot.

Once you've placed all your components, you can reflow the board to melt all the solder in place at once. See our ”How to reflow“ page for how to use the reflow oven.